high quality centrifugal slurry pump spares suppliers

Latest articles

What is a slurry pump?

high quality centrifugal slurry pump spares suppliers...

high quality centrifugal slurry pump spares suppliers 【high quality centrifugal slurry pump spares suppliers】

Read MoreDefinition of dredge and slurry pumps

high quality centrifugal slurry pump spares suppliers...

high quality centrifugal slurry pump spares suppliers 【high quality centrifugal slurry pump spares suppliers】

Read More- transport solids hydraulically

high quality centrifugal slurry pump spares suppliers...

high quality centrifugal slurry pump spares suppliers 【high quality centrifugal slurry pump spares suppliers】

Read MoreStep 1

high quality centrifugal slurry pump spares suppliers...

high quality centrifugal slurry pump spares suppliers 【high quality centrifugal slurry pump spares suppliers】

Read Moresets or tons on high chrome alloy castings. Main products are Type WA, WG, WL, WN, WY, WZ, etc. Size: 25-1200mm,

high quality centrifugal slurry pump spares suppliers...

high quality centrifugal slurry pump spares suppliers 【high quality centrifugal slurry pump spares suppliers】

Read MoreThe terms slurry pump and dredge pump can be used interchangeably.

high quality centrifugal slurry pump spares suppliers...

high quality centrifugal slurry pump spares suppliers 【high quality centrifugal slurry pump spares suppliers】

Read MoreImproved flow control

high quality centrifugal slurry pump spares suppliers...

high quality centrifugal slurry pump spares suppliers 【high quality centrifugal slurry pump spares suppliers】

Read Moresets or tons on high chrome alloy castings. Main products are Type WA, WG, WL, WN, WY, WZ, etc. Size: 25-1200mm,

high quality centrifugal slurry pump spares suppliers...

high quality centrifugal slurry pump spares suppliers 【high quality centrifugal slurry pump spares suppliers】

Read MoreRubber Lined Slurry Pump

high quality centrifugal slurry pump spares suppliers...

high quality centrifugal slurry pump spares suppliers 【high quality centrifugal slurry pump spares suppliers】

Read MoreThe construction aggregate industry conveys all forms of slurry, from fine sand to coarse aggregates.

high quality centrifugal slurry pump spares suppliers...

high quality centrifugal slurry pump spares suppliers 【high quality centrifugal slurry pump spares suppliers】

Read More

Popular articles

- How to Choose a Dredging Pump or Slurry Pump

- Customised solutions

- Especially when the dredging depth reaches 20m or more, the above situation will be more obvious. The use of underwater pumps can effectively improve the above situation. The lower the installation position of underwater pumps, the smaller the suction resistance and vacuum, which can obviously reduce the losses during the work and improve the working efficiency. The installation of underwater pump can effectively increase the dredging depth and improve the ability to transport sediment.

- Rubber Lined Slurry Pump

- Less downtime

- How does a dredge pump work?

Latest articles

-

TL FGD Pump

-

When the slurry pump working, pump parts are easy to be impacted, wear, and corrosion, etc. Therefore, the liner of the slurry pump uses wear-resistant material, such as high chromium alloy, rubber. The wear-resistant materials can effectively reduce the wear parts of the pump. So most of the slurry pump is a wear-resistant slurry pump in the current market.

-

Expertise and experience

-

WA series target=_blank title=Heavy-Duty Slurry Pump>heavy-duty slurry pump is cantilevered, horizontal, natural rubber or hard metal lined centrifugal slurry pumps. They are designed for handling abrasive, high density slurries in the metallurgical, mining, coal, power, building material and other industry department.

-

In addition, a new level of complexity is added to an otherwise simple machine. Other parts must now be inventoried and training beyond basic spanner turning is required. When it comes to pumping rock and some of the world's most abrasive materials.

-

Rubber lined pumps offer many advantages

Links

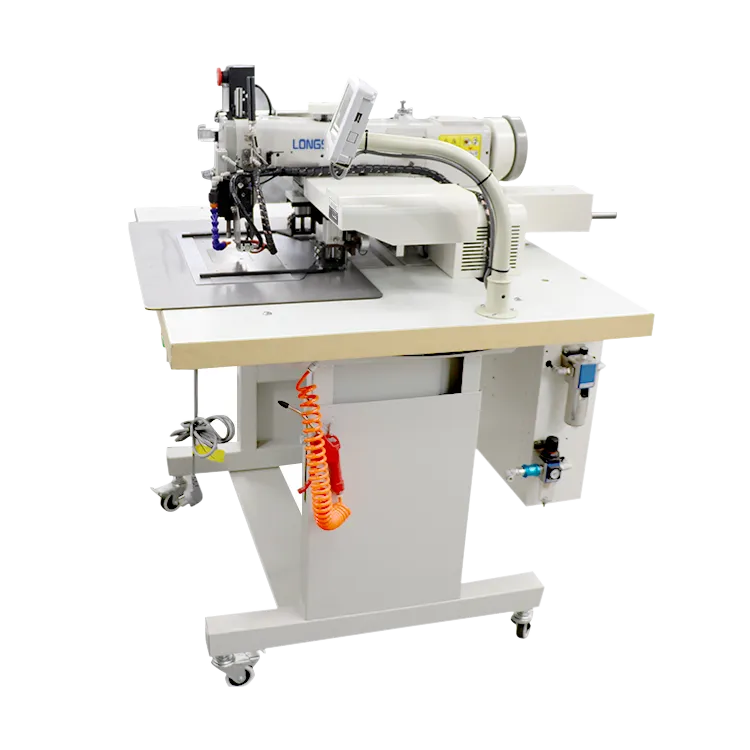

What Does a Computerized Sewing Machine Do?

It also boasts a high-speed sewing capability, enabling you to complete projects efficiently without compromising on quality It also boasts a high-speed sewing capability, enabling you to complete projects efficiently without compromising on quality

It also boasts a high-speed sewing capability, enabling you to complete projects efficiently without compromising on quality It also boasts a high-speed sewing capability, enabling you to complete projects efficiently without compromising on quality cb3200 sewing machine for sale.

cb3200 sewing machine for sale.One of the key benefits of automatic button sewing machines is their precision. The machines come equipped with various settings that can be adjusted according to the size and type of button being used. This ensures that each button is securely attached to the fabric without the risk of damaging the garment. The accuracy of these machines also minimizes the likelihood of human error, which can lead to misaligned or poorly attached buttons that may need to be redone.

automatic button sewing machine

This feature is especially useful when working with multiple layers of fabric, such as quilts, leather, or sewing intricate patterns. The walking foot mechanism provides uniform tension and consistent stitch quality, resulting in professional-grade finishes that are often hard to achieve with standard machines.

When selecting a heavy-duty sewing machine as a beginner, consider the following factors

6. Stitch Type and Length

Precision in Sewing Operations